What is the difference between 180-degree and 360-degree dye sublimated socks?

Which type of custom socks should you pick for your brand? 180-degree dye sublimated socks or 360-degree dye sublimated socks? What is the difference? Are they the same as printed socks? Learn more.

The dye sublimation process involves creating a deep print of your design onto the sock’s fabric with heat transfer. Using this process, you can get socks with rich details of your design and long-lasting images with vibrant colors.

Dye sublimated socks are also called printed socks.

180-degree dye sublimated socks:

180-degree dye sublimated socks

Image via Firebirdsocks

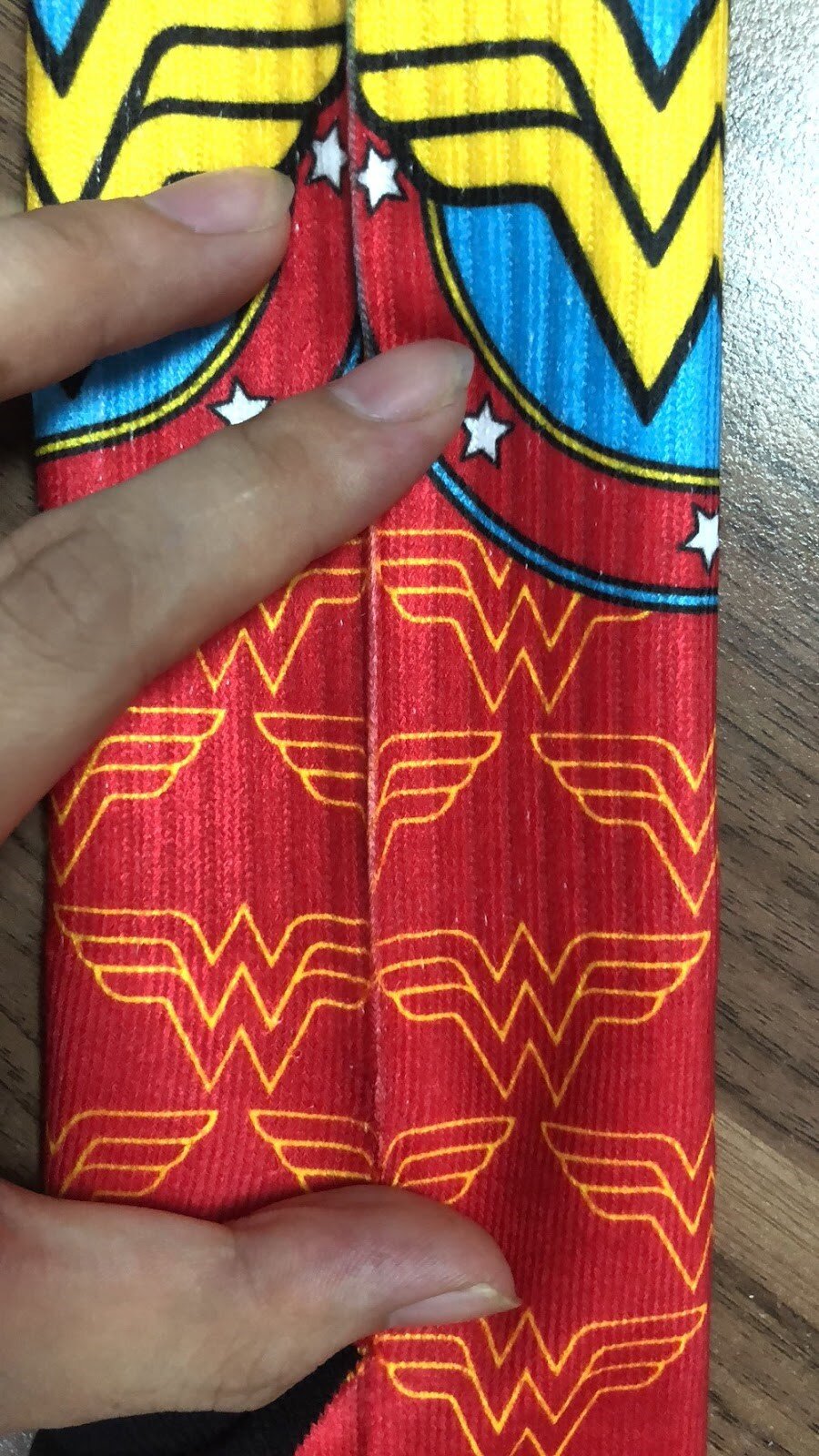

In 180-degree dye sublimation, the design can be printed onto the front of the socks or back or both. If you want the design on the side of the socks, it will stagger and you will be able to see the side seams.

180 sublimation socks are normally made with polyester.

Seams visible on a 180-degree dye sublimated sock

360-degree dye sublimated socks:

Seamless printing of design through 360-degree dye-sublimated socks

Image via Sockdreams

360-degree printing is an upgrade to the dye-sublimation process. It allows you to design a sock that has the graphics covered almost seamlessly. It enables greater color permeability, and even when the socks are stretched, the image looks great. There are no ‘white gaps’ in the socks when you use this method.

360 sublimation socks can be made with different materials such as a blend of polyester, cotton, spandex, etc. This makes the socks have a better stretch as compared to 180-degree sublimated socks which are made of 100% polyester.

Also, 180-degree socks lose shape more easily after multiple washes as compared to 360-degree socks

Both 180 and 360-degree socks are printed on a white base.

Cost: 180-degree vs 360-degree dye sublimated socks

“Printed using special machines which ensure that the design is all over the socks, 360-degree printed socks are more expensive than 180 degree printed socks”

The Verdict

Pick 180-degree socks when:

You have a design that can’t be knitted directly onto the sock fabric.

You are on a tight budget but want colorful printed socks.

You plan to give these socks as swag at universities/clubs, marathons, etc.

Pick 360-degree socks when:

You have a design that can’t be knitted directly onto the sock fabric. Your design is colorful and complex.

You need excellent quality printing on your socks, with no gaps to show.

You want the socks to offer a better stretch to the user.

You want the socks to be more durable and hold their shape even after multiple washes.

You plan to give these socks as corporate giveaways, in media swag bags, to clients, etc.

To know more about different types of sock fabrication, and the one that best suits your requirement, get in touch with us at sales@gumtoo.ca today.